Linear Guide or Box Guide

- What

is Box Glide System, When Should It Be Preferred?

- What

are the Advantages and Disadvantages of Box Guide System?

- What

is Linear Guide, what are the Types of Linear Guide System?

- What

are the Advantages and Disadvantages of Linear Guide System?

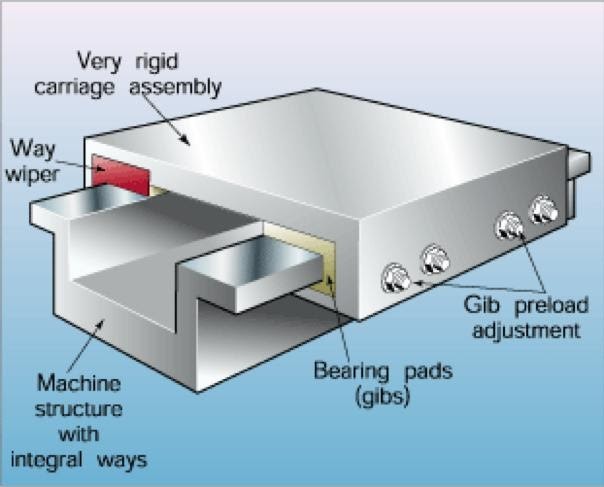

What is Box Guide System?

The main operating principle of this guide system, which is called

hydrostatic friction or box guide, is that the registration and guide equipment

work by providing superficial contact on each other. In this system, there is a

gap of up to 5 microns (0.005mm) between the register and the guide, and this

gap contains oil like a film strip in order to ensure the movement without any

problems.

Advantage of Box Guide:

- High rigidity,

- Low vibration,

- Better shock absorption,

- Strong and deep cuts,

- Compatibility with all kinds of materials.

Disadvantages of Box Guide:

- Slow idle speed,

- High production cost,

- Low precision,

- High maintenance cost,

- Excessive lubricant consumption.

When is Box Guide Preferred?

In CNC Machine Tools, generally box guide should be preferred if;

- the

material to be processed is hard,

- the

work piece to be connected is heavy (Generally Machining Centers),

- When

knocking and impact work pieces need to be cut,

- In

case cutting by high stock removal with deep depths of cut is desired,

- If

regular maintenance and costs are not overlooked.

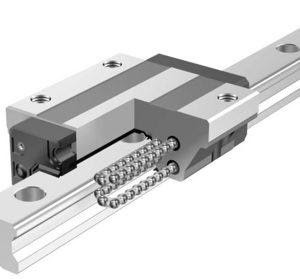

What is Linear Guide System?

In this guide system, which is

named as linear guide way, register and guide are replaced by trolley

and guide. These two pieces of equipment move by rolling the spacers that we

call ball or roller on each other. In this system, there is lubricant on the

surface where the roller or ball touches. However, a small amount of

lubrication is sufficient as there is rolling instead of rubbing surfaces in

the movement.

Ball Linear Motion System

Advantages of linear guide system:

- High speed movements,

- Much more precise measurement accuracy,

- Long service life,

- Low production cost,

- Low maintenance cost.

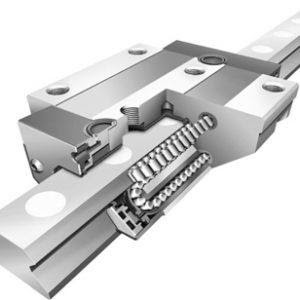

Roller Linear Motion System

Disadvantages of linear guide system:

- Relatively lighter cutting operations,

- Higher chance of vibration,

- Low precision,

- Not suitable for processing all types of materials,

- It can be easily damaged in accidents.

Additional info: The

disadvantages stated for linear guide systems are less in roller linear

guide systems compared to ball guide systems.

When is Linear Guide Preferred?

Linear Guide in CNC Machine Tools;

- In case speed matters in total processing time,

- If the tolerances in the work pieces are narrow (high

measurement precision),

- When it is desired to process relatively smoother work pieces,

- When cutting is not required with too much cut depth,

- In case regular maintenance and costs are not overlooked.

|

Ball Linear Guide |

Roller Linear Guide |

Box Guide |

|

|

Rigidity Ratio |

50-70% |

70-90% |

100% |

|

Idle Speed |

100% |

100% |

(Max).30% |

|

Movement Speed When Cutting |

100 m/min |

100 m/min |

20 m/min |

|

Friction Rate |

5-20% |

10-30% |

100% |

Considering the above information, it is

absolutely not correct to say that any of the Linear motion systems or Box

Guide (Friction Slide) systems are completely superior to the other. The main

thing here is to choose a suitable motion system for the job to be done.

- Manufacturers have gradually reduced the production of Box Guide systems due

to the high production and maintenance & repair costs in CNC

machine tool production, and they prefer to use Linear systems if they are

not necessary.

TR

TR

EN

EN